The Story

As a company that values sustainability and the well-being of our planet, we are always on the lookout for new and innovative ways to create products that not only serve their intended purpose but also have a positive impact on the environment. When Apple first introduced the concept of MagSafe in 2020, we saw an opportunity to take this technology and put our own unique spin on it, with the goal of making it an even more eco-friendly and sustainable option.

With this in mind, we set out to develop a product that not only incorporated the benefits of MagSafe but also leveraged materials and manufacturing processes that were environmentally responsible.

As always we first discussed and dreamed with our design team locally in Sweden. Why should a magnet with a lifespan of maybe 15 years, be a permanent part of a phone case? Shouldn’t they be separate so the MagSafe can move from case to case? Especially since we know that the average phone user changes their phone every 21 months; this can become extremely wasteful. By carefully listening to our design team in Sweden, we came up with a unique solution – the agood MagSafe. Our agood MagSafe is the perfect way to make your phone sustainable, stylish and durable with our agood phone case.

How we found it

Our local sourcing team, Kate and Bob, set out in Hong Kong to find the best breed of magnets, without compromising on sustainable production. We once again reached out to our long-term favorite material, stone paper, which we use to make our stone paper notebook, to serve as a piece of the puzzle. We believe every single aspect of agood company products should reflect our stance on sustainability, even the packaging.

You can watch the MagSafe packaging process here.

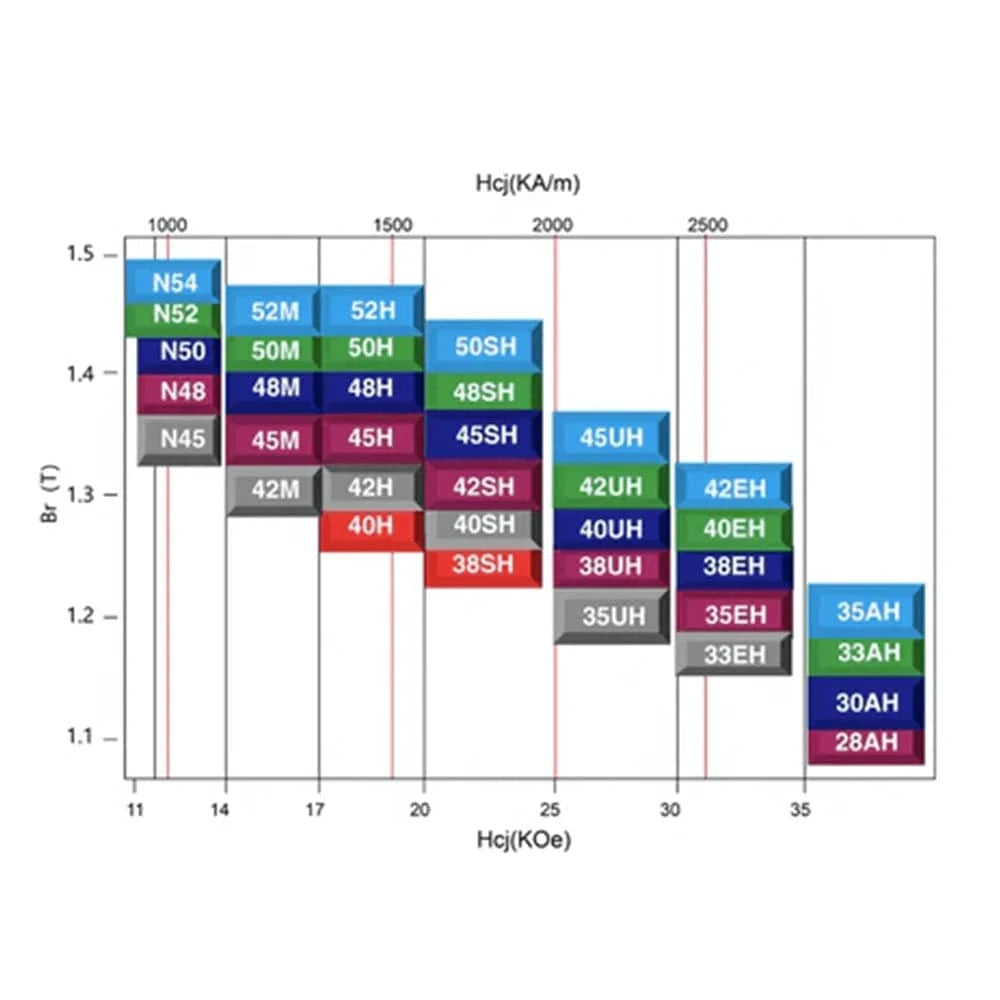

Finding strong N52 magnets was key, and after numerous visits to the factory, we decided it was a good fit. The factory is privately owned and holds a professional industrial wastewater recycling station, recycling regularly, and hydraulic electro generating for heating.

The process and way of working

A sustainable MagSafe ring sounds pretty amazing, right? Our goal was to create a product that is not only functional and stylish but also environmentally conscious.However, the process of making a ring that can move from case to case is far from easy, but well worth it. The manufacturing process include the following steps:

- Magnets are ordered from a sustainable source, and are subjected to extensive testing to ensure their quality.

- To minimize waste and support our commitment to sustainability, we avoid using plastic packaging for the magnets.

- The magnets are carefully attached to stone paper packaging, which is eco-friendly and biodegradable.

- The packaging, along with the magnets, are then placed into bamboo paper boxes, which are also sustainable and biodegradable.

- The entire manufacturing process is quite manual, as magnets are both precious and expensive, and require careful handling, you can check out part of the process here.

- We exclusively purchase Apple-certified magnets to ensure that our MagSafe rings are compatible with all Apple products.

- Social sustainability is also a key priority for us, and we work only with partners who provide fair living wages and safe working conditions for their employees.

At our company, we also believe in the importance of social sustainability, which is why we carefully select partners that share our values. The factory we work with is committed to fair labor practices, paying their workers a fair living wage and employing a workforce that is 56% female in production and 36% female at their headquarters. We maintain close contact with the factory to ensure that everything is managed correctly, and we are proud to work with such a reputable partner.

About the owner

The factory where the sustainable MagSafe ring is manufactured is located in China and was founded on March 16th, 2006 by GuangFei Xiang. With over 16 years of experience in the magnet industry, he has become an expert in the field and is now the CEO of three companies, all specializing in magnetic products.

In order to ensure the highest quality of materials, the factory sources its raw materials from state-owned enterprises such as Baogang Group, TianHe Magnetics, and Jinshan Magnetic Material Co., Ltd. These enterprises are known for their expertise in manufacturing neodymium material, which is used in the production of the MagSafe ring. The neodymium material has high quality and stable performance, ensuring the longevity and durability of the MagSafe ring.

In addition to using high-quality materials, the factory also prioritizes sustainability. The factory utilizes professional industrial wastewater recycling stations on a regular basis to minimize waste and reduce their environmental impact. All of the recycling stations are compliant with recycling standards, ensuring that the factory is operating in an environmentally responsible manner.

Overall, the factory is dedicated to producing a sustainable MagSafe ring that meets high standards of quality and environmental responsibility. Through careful sourcing of materials and utilization of sustainable manufacturing practices, the factory is able to create a product that is both innovative and socially responsible.

Conclusion

In conclusion, the agood MagSafe is not just a phone accessory, but a symbol of our commitment to sustainability and the environment. By combining innovative technology with sustainable materials and ethical manufacturing practices, we have created a product that not only serves its intended purpose but also has a positive impact on the world. From the sourcing of sustainable magnets to the use of biodegradable packaging, every aspect of the manufacturing process has been carefully considered to ensure that our product is environmentally responsible. By choosing the agood MagSafe, you are making a conscious decision to support a more sustainable future.